Milling Machines

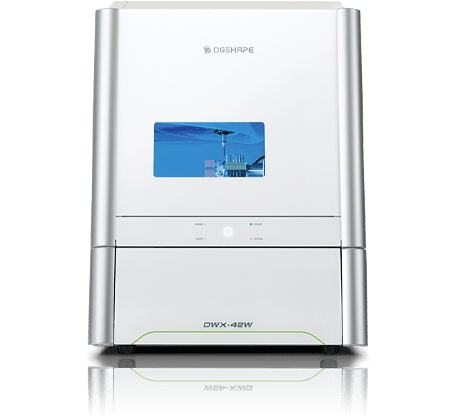

Roland DWX-42W

The DGSHAPE DWX-42W enables wet milling of popular glass ceramic and composite resins with high precision and accuracy. From in-clinic to dedicated high-production labs, the DWX-42W is engineered to fit your milling needs. It provides high speed production with proprietary DGSHAPE spindle.

Features

- High speed production with proprietary DGSHAPE spindle

- Expanded 6-tool Automatic Tool Changer for uninterrupted milling

- LAN capable for easy connectivity

- Included VPanel for easy monitoring of milling jobs and tools

Specs

- Millable Material: Glass ceramics, Composite resin, PMMA

- Loadable Workpiece Shape: Width – Maximum 40 mm; Depth – Maximum 20 mm; Height – Maximum 20 mm

- Operating Speed: 0.24 to 70.9 in./min. (6 to 1,800 mm/min.)

- Spindle Speed: 15,000 to 60,000 rpm

- Rotary Axis Travel Angle: ±360°

- Number of Burs Housed: 6

- Attachable Bur: 3 mm, dedicated milling bur

- Compatible Compressed Air: Control Pressure – 0.3 MPA or more; Air Capacity – 39 L/min or more

- Interface: USB, Ethernet (10 BASE-T/100 BASE-TX automatic switching)

- Control Command Set: RML-1, NC code

- Power Requirements: AC 100 to 240 V ± 10%, 50/60 Hz (overvoltage category II, IEC 60664-1), 2.1 A

- Power Consumption: Approximately 190 W

- Operating Noise: During Operation – 70 dB(A) or less (when not cutting); During Standby – 48 dB(A) or less

- External Dimensions: 19.0 x 22.0 x 23.6 in. (482 x 560 x 600 mm)

- Weight: 135 lbs. (61 kg)

- Installation Environment: Indoor Use, Altitude – Up to 6,562 ft. (2,000m); Temperature – 41 to 82 °F (5 to 28°C); Humidity – 35 to 80%RH (no condensation); Ambient Pollution Degree – 2 (as specified by IEC 60664-1); Short-Term Temporary Overvoltage – 1,440 V; Long-Term Temporary Overvoltage – 490 V

- Included Items: Power cord, USB cable, Roland DG Software Package CD, setup guide, drain hoses, dedicated milling burs (4), detection pin, dummy pin, rotary axis correction jig, ATC magazine correction jig and screw, hexagonal screwdriver, hexagonal wrench, measuring cup, mounting screws (4), milling bur removal jig, coolant tank, waste receptacle, filters (2), regulator with stay and screws (2), maintenance kit, daily maintenance card, 6 mm air hose, coolant additive, MillBox CAM software, Ethernet cable